CAREERS

WORK WITH US - CAREER DEVELOPMENT

Our goal here at LA Aluminum is to be the preferred manufacturer of permanent mold aluminum castings.

To meet this goal, we rely on our talented and dedicated workforce. Our vision is to be a preferred employer. We are committed to developing employee potential and opportunities for career growth.

Whether you are looking for a position on our team where you and your skills can make a difference, or want to develop new skills and strengths, there may be career opportunities for you at LA Aluminum.

There are four ways to apply:

- Complete the online application below

- Email your resume to: [email protected]

- Download application and email to: [email protected]

- Fill out an application in person at LA Aluminum, 1906 W Miles Ave, Hayden, Idaho

We will contact applicants if a position is available or becomes available.

Benefits

- Competitive Pay

- Referral Bonuses

- 401(k) Retirement Plan

- 401(k) Matching

- Uniform Reimbursement

- PTO + 6 Paid Holidays

- Employee Luncheons

- Dental Insurance

- Health Insurance

- Vision insurance

- Life Insurance

- Spirit Wear/Swag

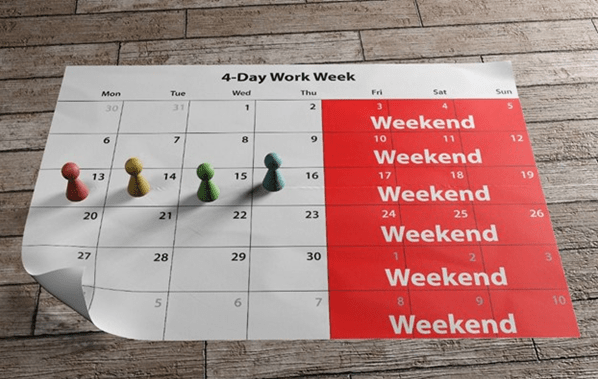

- 4-day Work Week

OPEN POSITIONS

SWING SHIFT MACHINE SHOP OPERATOR

Job description

The objective of this role is to help make LA Aluminum Casting Company operations run efficiently. This individual should have the ability to work as a team, make decisions about the parts they are handling, and work closely with their supervisor to ensure the proper handling of parts. Being a friendly, self-motivated team player with strong interpersonal skills is necessary for this role.

Job Description: Performs the essential tasks of operating the CNC Mill/Lathe Machines

Duties & Responsibilities:

- Load and run parts into CNC Mill/Lathe machines

- Maintain production efficiency levels

- Keep machine tools in clean and working order

- Fill out inspection first article and in process reports

- Report machine issues

- Communicate, support and reinforce the values of the organization professionally

- Work in a team environment and be supportive of all company initiatives

- Maintain a safe and organized work area

Qualifications:

Physical Demands

Must be able to stand, push, pull, reach and bend to the floor and must be able to occasionally push up to 50 lbs.

Hearing Ability

No special requirement

Working Conditions

Works on the shop floor, may be subject to

- High levels of noise

- Physical hazards of moving equipment and machine parts.

- Flying cutting fluid and coolant

- Varying degrees in temperature

Work Experience

No Experience Required but preferred

Schedule: Monday through Thursday 4-10 hour shifts, occasional Friday’s-overtime.

Job Type: Full-time

Pay: $20.00 – $25.00 per hour

Expected hours: 40 per week

Benefits:

- 401(k)

- 401(k) matching

- Dental insurance

- Employee assistance program

- Health insurance

- Health savings account

- Life insurance

- Paid time off

- Referral program

- Retirement plan

- Vision insurance

Schedule:

- 10 hour shift

- Evening shift

- No weekends

Education:

- High school or equivalent (Preferred)

Work Location: In person

CONTACT US

Phone: 208-772-3201

Email: [email protected]

Address:

LA Aluminum Casting Company

1906 W. Miles Ave.

Hayden, Idaho 83835